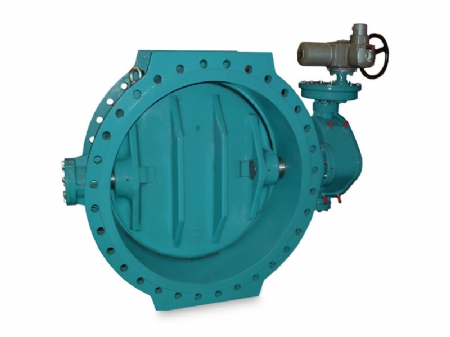

Kelebek Vanalar: Genel Bakış ve Özellikler

Kelebek vanalar, sıvı ve gaz akışını kontrol etmek için kullanılan popüler vana türleridir. Özellikle boru hatları sistemlerinde yaygın olarak tercih edilen bu vanalar, döner bir disk mekanizmasıyla çalışır. İşte kelebek vanaların temel özellikleri ve avantajları:

Temel Özellikler:

- Yapı: Kelebek vanalar, merkezi bir eksende dönen disk veya plakadan oluşur. Disk, vananın açılmasını veya kapanmasını kontrol eder.

- Fonksiyon: Diskin konumuna göre akışkanın geçiş yolu açılır veya kapatılır. Genellikle 90 derece döner, bu da vananın tamamen açık veya kapalı olmasını sağlar.

- Malzeme: Çeşitli malzemelerden üretilebilir, bu da farklı endüstriyel ortamlar için uygun olmasını sağlar.

Avantajlar:

- Kompakt Tasarım: Diğer vana türlerine kıyasla daha kompakt ve hafif bir yapıya sahiptir, bu da kurulum ve bakım sürecini kolaylaştırır.

- Hızlı Açma ve Kapama: Hızlı açma ve kapama yeteneği sayesinde, akışkanların hızla yönetilmesini sağlar.

- Düşük Basınç Düşüşü: Tasarımı, akışkanın akışında minimum basınç kaybı sağlar, bu da enerji verimliliğini artırır.

- Çeşitli Uygulama Alanları: Su arıtma tesislerinden, petrol ve gaz endüstrilerine, kimya ve enerji sektörlerine kadar geniş bir uygulama yelpazesi sunar.

Kullanım Alanları:

- Su ve Atıksu Yönetimi: Su arıtma tesislerinde ve atıksu sistemlerinde kullanılır.

- Petrol ve Gaz: Boru hatlarında akış kontrolü sağlar.

- Kimya ve İlaç Sektörleri: Kimyasal ve farmasötik maddelerin yönetiminde kullanılır.

- Enerji ve Güç Üretimi: Enerji santrallerinde ve buhar sistemlerinde yaygın olarak kullanılır.

Kelebek vanalar, sağlam performansı, enerji verimliliği ve esneklikleri sayesinde birçok endüstriyel uygulamada tercih edilen çözümler sunar. İhtiyacınıza uygun çözümler ve daha fazla bilgi için bizimle iletişime geçebilirsiniz.