Çek Valfler: Genel Bakış ve Özellikler

Çek valfler, akışın yalnızca bir yönde gerçekleşmesini sağlayan ve ters akışı engelleyen vanalardır. Çeşitli endüstriyel uygulamalarda kullanılan bu valfler, sistemlerdeki geri akışı önleyerek ekipmanların ve tesislerin korunmasına yardımcı olur. İşte çek valflerin temel özellikleri ve avantajları:

Temel Özellikler:

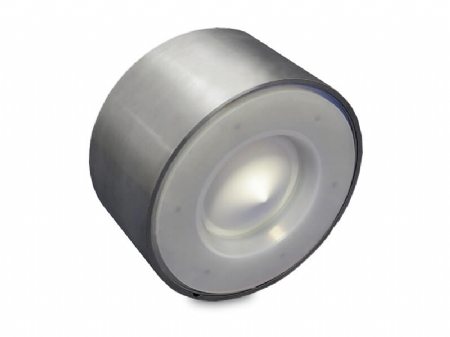

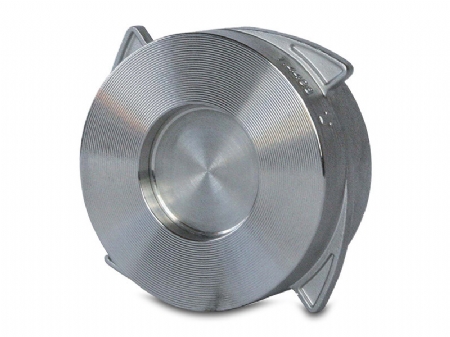

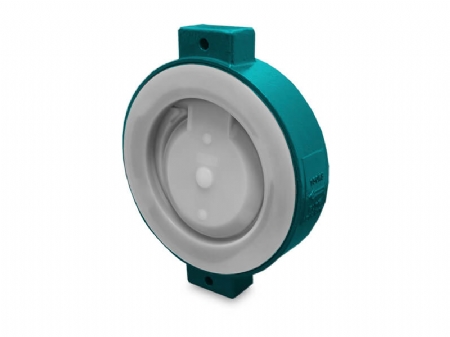

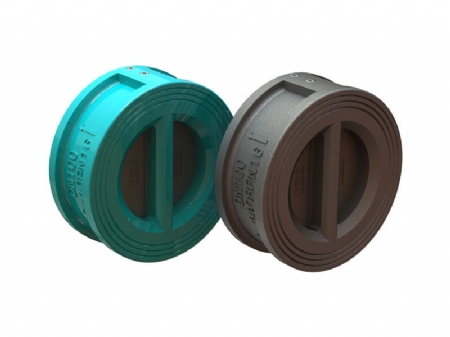

- Yapı: Çek valfler, içlerinde akışın tek yönlü olmasını sağlayan bir mekanizmaya sahiptir. Bu mekanizma, genellikle yaylı bir kapak veya serbest hareket eden bir disk olabilir.

- Fonksiyon: Akış ileri yönde olduğunda valf açılır, ters yönde olduğunda ise kapanarak geri akışı engeller.

- Malzeme: Çeşitli malzemelerden üretilebilir, bu da farklı endüstriyel uygulamalar için uygun olmasını sağlar.

Avantajlar:

- Geri Akış Önleme: Çek valfler, sistemlerde geri akışı engelleyerek ekipmanların ve boru hatlarının korunmasına yardımcı olur.

- Düşük Bakım Gereksinimi: Basit tasarımları sayesinde çek valfler, genellikle düşük bakım gerektirir.

- Enerji Verimliliği: Düşük basınç kaybı ile enerji verimliliği sağlar, bu da sistemin genel performansını artırır.

- Çeşitli Uygulama Alanları: Su ve atıksu yönetiminden, petrol ve gaz endüstrisine kadar geniş bir uygulama yelpazesi sunar.

Kullanım Alanları:

- Su ve Atıksu Yönetimi: Su pompaları ve atıksu sistemlerinde geri akışı önlemek için kullanılır.

- Petrol ve Gaz: Boru hatlarında ve rafinerilerde akış kontrolü sağlar.

- Kimya ve İlaç Sektörleri: Kimyasal maddelerin taşınmasında geri akışı engeller.

- Enerji ve Güç Üretimi: Enerji santrallerinde ve buhar sistemlerinde kullanılır.

Çek valfler, güvenilir performansları ve düşük bakım gereksinimleri ile birçok endüstriyel uygulamada tercih edilen çözümler sunar. İhtiyacınıza uygun çözümler ve daha fazla bilgi için bizimle iletişime geçebilirsiniz.